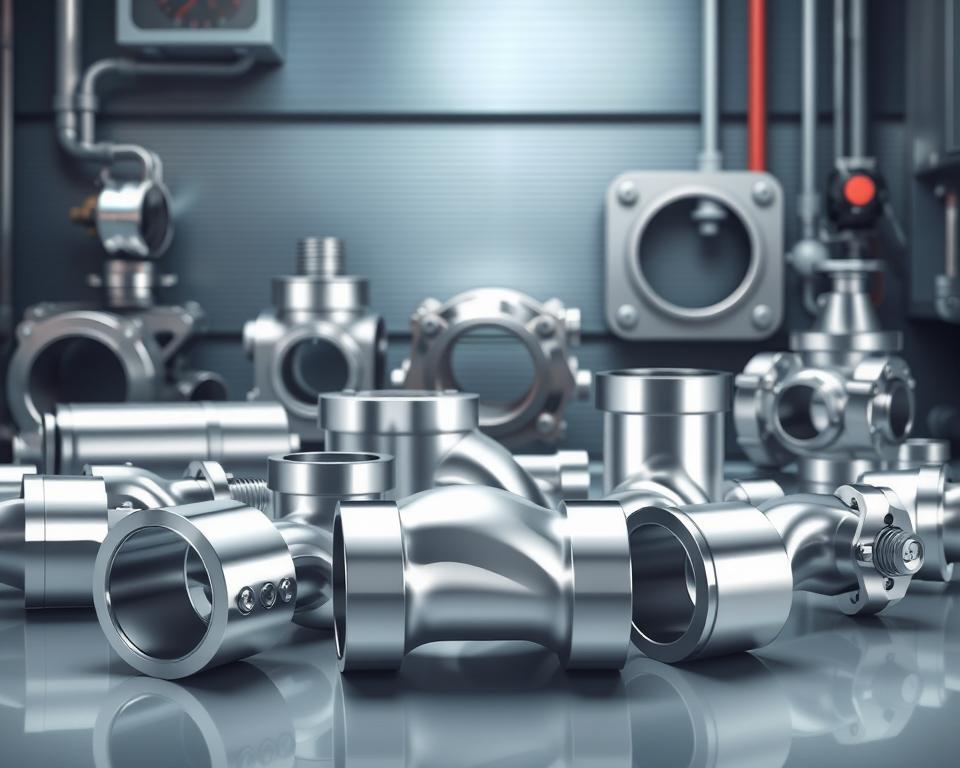

Superior Tri-Clover Clean-Flow Fittings for Sterile Environments

Whenever cleanliness saves lives, even tiny voids pose a risk. Therefore, companies like Installation Parts Supply offer expertly engineered solutions minimizing contamination. Their hygienic connection systems blend long-lasting strength with seamless assembly, positioning them as a top choice for plants that must avoid shortcuts.

These elements offer more than avoiding seepage – they’re engineered to satisfy the rigorous needs of edible-product processing, beverage production, and biopharma plants. Constructed with rust-proof metals, they withstand ongoing sanitizations while preserving strength. The build mindset reflects industry leaders like Alfa Laval, placing first sanitary flange smooth surfaces and rapid breakdown.

What sets these products apart? Think single-handed setup and tool-free maintenance. Technicians value the straightforward build during busy shifts, while supervisors cherish standardized performance across pipelines. Every piece receives rigorous inspections to ensure compliance with FDA and 3-A Sanitary Standards.

Primary Conclusions

- Preferred by technicians for fluid-tight security in sensitive settings

- Constructed with premium stainless steel for lasting durability

- Streamlines adherence to food safety and pharmaceutical rules

- Shrinks production pauses through hand-tightened buildup and washdown

- Underwritten by inspection regimes equalling global benchmarks

Overview & Primary Benefits

Reliable connections are the backbone of clean-room activity. Installation Parts Supply creates components that merge precision engineering with real-world usability. Their solutions deliver sealed reliability while making upkeep easy—critical for fields where fast output meets strict hygiene.

First-Class Quality and Clean Standards

Every unit faces intensive trials to comply with worldwide norms. The alloys fight rust and pockmarks, even after repeated sterilization cycles. Fluid-tight rings block pathogen buildup, a feature valued by dairy processors and pharmaceutical manufacturers alike.

These couplings match the standards of leaders like Alfa Laval, ensuring smooth surfaces and uniform dimensions. Flexible configurations integrate with legacy piping, lowering modification spend. Crew note 30% speedier setups compared to traditional threaded systems.

Why Choose This Supplier

Bespoke machining raises IPS above peers. Looking for unusual geometry or rare plating? Their team works hand-in-hand with customers to deliver custom parts. Same-day shipping and 24/7 technical support reduce downtime.

The benefits go past toughness. No-tool breakdown reduces lag during microbial reviews. Bottling facilities using these connectors report fewer production stoppages and balanced streams. It’s not just about hitting the rules—it’s about surpassing them with ease.

Design Highlights & Technical Notes

Precision engineering marries multi-purpose use in today’s process plants. Installation Parts Supply creates components that balance stringent tolerances with customizable setups. Their method secures easy incorporation into installed systems while preserving strict hygiene protocols.

Material Choices & Surface Treatments

Specific processes call for tailored gear. That’s why options span 304 through 316L stainless, opted for strength and corrosion resistance. Surface treatments like electro-shining form mirror-like smoothness, lowering germ cling by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes leverage laser measurement tools to ensure uniform wall thickness. Tight tolerances (±0.005″) banish thin walls in elevated-pressure rigs. During quality checks, components face X-ray scans and pressure tests to identify microscopic flaws.

Adaptability goes past appearance. Clients specify precise degree-turns, flange sizes, or custom coatings for chemical resistance. These made-to-order choices help industries keep pace with changing codes without re-engineering full setups.

Installing & Using Tri-Clamp Fittings

Contemporary rapid-run factories require parts that install quickly yet run dependably. These coupling sets perform best in environments where quickness aligns with sanitation. Their design does away with heavy tooling, letting teams to stay productive rather than setup struggles.

Quick-Install Workflow

Dual flange faces and a centered gasket generate foolproof seals in seconds. Crew align the parts, insert the hinged clamp, and secure manually – no wrenches required. This method minimizes assembly faults while maintaining consistent pressure across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Convertible Connections for Gear

From stainless steel tubes to processing equipment, these interfaces link unlike gear seamlessly. The uniform design works with various diameters, supporting speedy swaps during product changeovers. Dairy plants regularly utilize them to alternate between cleaning cycles and production runs without hiccups.

Upkeep units like how components disassemble for thorough sanitation. Smooth surfaces halt grime collection, while the thread-free design avoids bacterial hideouts. Weekly cleanings require 50% less effort compared to older connection methods.

Market Adoption & Standard Adherence

Across nano-brew houses to biotech sites, modern facilities depend on parts that fit varying demands while aligning with strict codes. Installation Parts Supply provides solutions valued across sensitive industries where product purity is non-negotiable. Their designs connect throughput to legislation, building lines that excel under load.

Food, Beverage, and Pharmaceutical Sectors

In food and beverage plants, speedy-switch links simplify switching between recipes or cleaning cycles. Breweries employ dedicated tees to manage complex flow paths without cross-contamination risks. Pharmaceutical manufacturers trust sealed couplings to guard delicate ingredients during sterile transfers.

These links come in multiple sizes to match piping layouts, from benchtop rigs to large-scale fermentation tanks. Dairy processors commend how standardized parts cut line pauses during equipment upgrades. Even tiny alterations in production processes are handled through modular designs.

Meeting ASME, ISO & 3A Rules

Every unit hits or surpasses benchmarks set by global organizations. ASME-certified materials withstand heat in pasteurization systems, while ISO-compliant finishes resist pathogen growth. The 3-A symbol certifies compatibility for direct contact with consumables.

Tri-Clover joints demonstrate the devotion. Their uniform dimensions deliver impermeable results across automated lines. Third-party audits verify traceability from raw materials to finished goods, giving quality teams peace of mind.

By aligning with these standards, facilities smooth approval workflows and clear checks smoothly. It’s not just about escaping sanctions—it’s about securing customer faith through demonstrable safety practices.

Wrap-Up and Future Steps

Opting for fittings that link efficiency with standards steers process outcomes. Installation Parts Supply brings systems marrying longevity and hygiene, providing leak-free performance across food, pharma, and beverage environments. Their products conform to rigorous standards while making daily work simpler through simple fitment.

With selections covering grades and coatings, solutions tailor to distinct facility goals. Whether handling high-temperature fluids or recurring sterilizations, material choices and surface treatments optimize longevity. Professionals appreciate the vast catalogue of joints designed for specific flow rates and pressure demands.

Procurement stays smooth, with expert guidance available to suit project goals. Rapid dispatch and minimized wait times cut idle hours during upgrades or replacements. Routine maintenance becomes effortless thanks to hand-split fittings and glossy paths that block grime.

Prepared to boost plant dependability? Consult Installation Parts Supply to review personalized setups – from tri-clover to sanitary tri-clover links – reinforced by premium QC. Their team guarantees up-to-date conformity while gearing up for next-gen demands.